Please click below for more information on the Clark hydraulic grout pump and mixer.

View Data Sheet

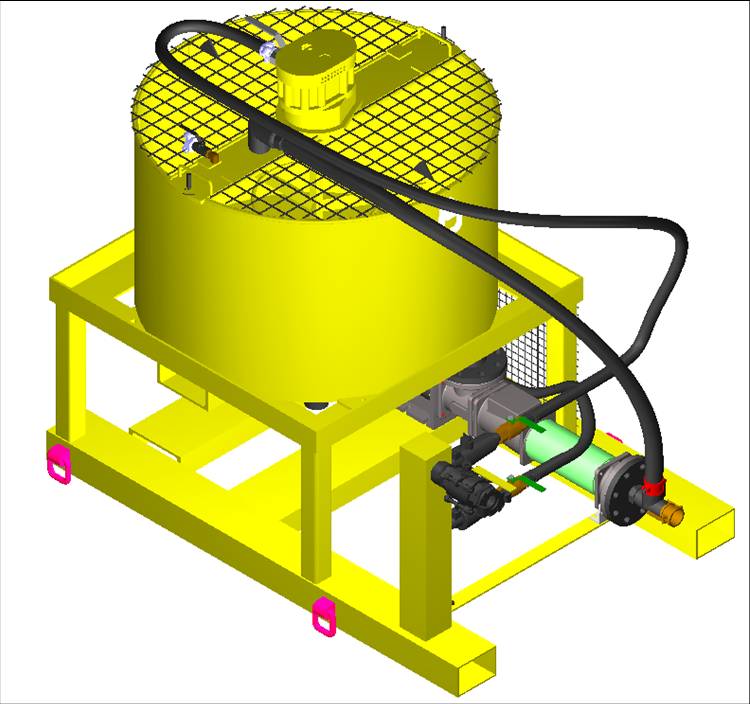

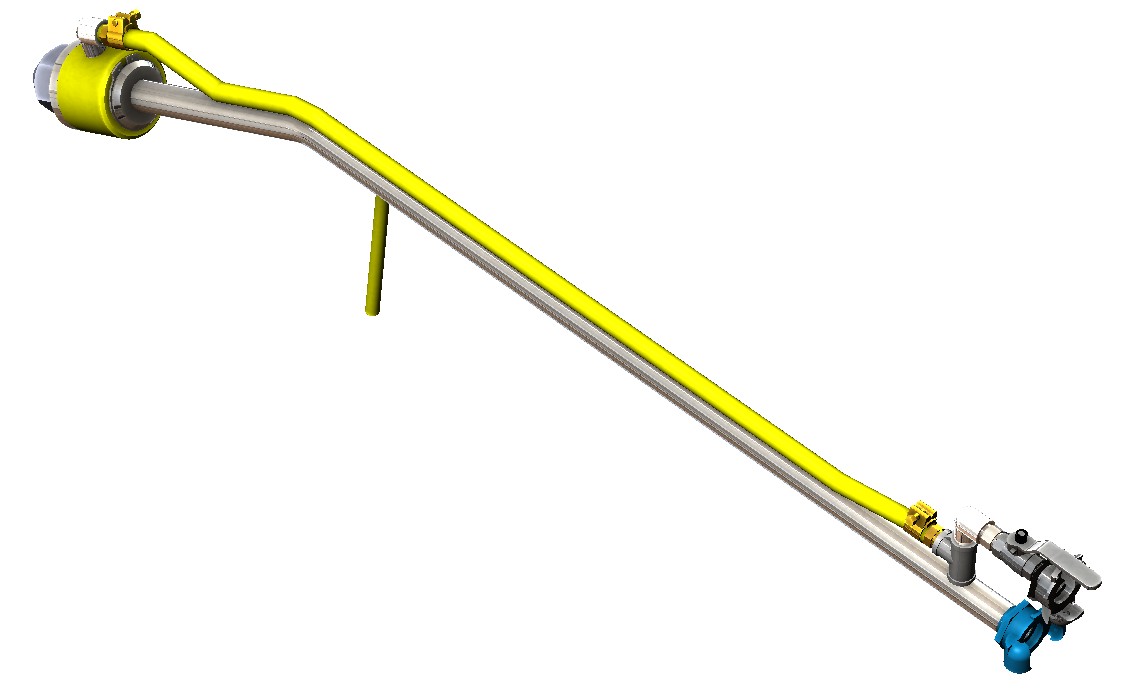

The pneumatic range of Clark Grout Pump and Mixers have been used in coal mining and civil construction applications for more than twenty years. The grout pump can be utilized for various applications. These include: pressure injection of cable bolts for roof and strata support; void filling of strata, either to atmosphere or injected with the Clark grout packer; spraying of ventilation stoppings in coal mines; spraying concrete on pylons and bridge repairs and also slab jacking. The grout pump options can be used in combination with the Clark Grout Mixers. Two different capacity mixers are available. The 150 litre capacity mixer is the most common size for easy handling in confined areas. For larger mixes, the 500 litre capacity mixers yield around 300 litres of grout per batch and have been used in may civil construction applications such as the strengthening of Sydney Airport runway. For underground coal applications such as cable bolting using Stratabinder or similar type grout, the M150 with the Mk2 mixer is recommended.For thicker grouts such as thixotropic grouts, the M150 with a thixotropic mixer is preferred.

Please click below for more information on the Clark hydraulic grout pump and mixer.

View Data Sheet

Please click the link below for more information on the Clark pneumatic grout pump & mixer range.

View Data Sheet

Please click below for more information on the Clark progressive cavity pump.

View Data Sheet

Please click below for more information on the Clark grout spray gun.

View Data Sheet